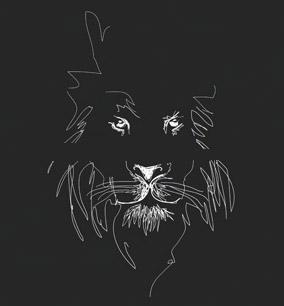

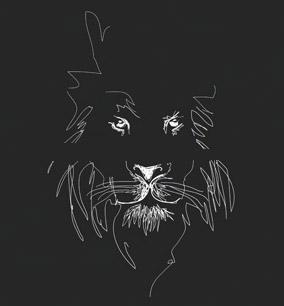

A wacom tablet sketch. Do you think this sort of thing is possible to

inlay? I was thinking maybe work with an extra fine bit for the routing,

and fill it in with some sort of colored dust? How would you approach it?

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| How would you inlay this? http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=7046 |

Page 1 of 2 |

| Author: | James Orr [ Thu Jun 08, 2006 7:36 am ] |

| Post subject: | |

A wacom tablet sketch. Do you think this sort of thing is possible to inlay? I was thinking maybe work with an extra fine bit for the routing, and fill it in with some sort of colored dust? How would you approach it?

|

|

| Author: | Michael Dale Payne [ Thu Jun 08, 2006 8:08 am ] |

| Post subject: | |

Black MOP ingrave and fill with white ingraving filler |

|

| Author: | John Mayes [ Thu Jun 08, 2006 8:34 am ] |

| Post subject: | |

I like the idea of getting a really fine bit (like .005-.010) and routing it out..very carefully. Like scribing it first, filling with chalk, and then routing over the top, and then filling it with some inlace (some pearlish or glittery color..you won't really see the glitter, but it'll give it some sparkle) The Black MOP is a decent Idea too. |

|

| Author: | A Peebels [ Thu Jun 08, 2006 9:22 am ] |

| Post subject: | |

Rectangular silver or gold wire. Look at some of the wire inlay on flintlock rifles from the 1700's. Al |

|

| Author: | James Orr [ Thu Jun 08, 2006 10:53 am ] |

| Post subject: | |

Thanks guys. I'd like to actually do it. It'd be my first inlay. This looks a bit less like a rabbit and more like a lion.

|

|

| Author: | Shawn [ Thu Jun 08, 2006 11:16 am ] |

| Post subject: | |

Inlace will work well...if you feel up to the challenge, silver or gold wire (.005-.010) would be killer. Gold wire (gold plate on brass alloy) would probably stand out more. Neither are expensive. If you are going to use a machine to do the rout (as opposed to by hand with a graver) then I would consider the mini-grinder (air powered) inlay router that John Hall (Blues Creek, a Sponsor) sells. It is a much higher speed than any kind of router, is easy to control and is very affordable. The choice comes down to a scratched (graver) surface that then gets fills with a contrasting fill or an inlaid surface (routed) that gets inlaid with wire, inace or other fill. Either way works and I agree, once you gave the lion a "haircut" he looks much better :) Good Luck |

|

| Author: | clavin [ Thu Jun 08, 2006 12:24 pm ] |

| Post subject: | |

Print it out at the size you want to inlay it at. Glue this down to the inlay surface with 3M tack glue. Route using a small bit (I use the stew-mac downcuts) through all of the lines and literally make the pattern you see into the image fully routed. Fill all the areas with thin gold wire (or silver/brass, copper whatever). Make sure your wire is thicker than the route or you'll lose areas below the surface. I would use gold pearl for the more full areas, then build around it. Oh- any kinks in the wire will also be tough to get out so take your time. Wire also raises when heated so sand slowly and carefully All metals heat up a lot when sanding. If this is your very first one let me start by saying "good luck"

Craig Lavin |

|

| Author: | A Peebels [ Thu Jun 08, 2006 12:25 pm ] |

| Post subject: | |

BTW the flat wire can be purchased from a lapidary supply house. Al |

|

| Author: | mikev [ Thu Jun 08, 2006 12:55 pm ] |

| Post subject: | |

John, do you know of such a router bit in .005 or .010. I would think these would be very brittle and very expensive. I work in circuit board manufacturing and we have drills down to .019". Looking at then crosseyed breaks 'em. I have often wanted to get smaller router bits then I have to get tigher in corners, mine are about .030 I think.. maybe 3/64". If you know of smaller sizes I would like to know where you get them. Mike |

|

| Author: | John Mayes [ Thu Jun 08, 2006 1:38 pm ] |

| Post subject: | |

I have a cousin who is a dentist and he gives me a lot of the dentil bits, plus you can get ones this thin in a little boxed set like at harbor frieght.. and yes they are very brittle... |

|

| Author: | mikev [ Thu Jun 08, 2006 1:53 pm ] |

| Post subject: | |

I just knew it was time for me to go see the dentist!! thanks John. |

|

| Author: | Michael Shaw [ Thu Jun 08, 2006 2:47 pm ] |

| Post subject: | |

I like the wire idea. Gold would fit the true color of a lion. Silver for the wiskers. |

|

| Author: | Shawn [ Thu Jun 08, 2006 3:01 pm ] |

| Post subject: | |

Milk dripping off the whiskers would be MOP?

|

|

| Author: | Joe Beaver [ Fri Jun 09, 2006 11:56 am ] |

| Post subject: | |

Need small end mills? Try here. I like the Microcut they sell. They are good quality and around $10 each. Come in a multitude of sizes. (they are on the site but it is a little hard to navigate. That is an ambitious inlay project but it will be worth it!! http://www.american-carbide.com/ |

|

| Author: | James Orr [ Fri Jun 09, 2006 2:15 pm ] |

| Post subject: | |

Thanks guys, I really appreciate it. Do you think it's really all that ambitious? Granted, I've never done it, but wouldn't I rout the lines out carefully, then fill them with the dust? |

|

| Author: | Serge Poirier [ Fri Jun 09, 2006 2:30 pm ] |

| Post subject: | |

James, really nice project but if it's your first attempt at something so narrow, wouldn't it be sage to practice on scrap first? Just a thought. Serge |

|

| Author: | old man [ Fri Jun 09, 2006 2:51 pm ] |

| Post subject: | |

You can do it. I've done something similar. I use a 1/32"bit for fine lines like that. Just doing the lines and filling with inlace or sawdust is possible if you have a steady hand. Now, if you had to cut MOP or something to inlay, it would probably take a Craig or a Paul to do it. I'm not very experienced, but the first time I tried this was doing antennae on butterflies for a jewelery box inlay. The box was bubinga and I filled the lines with ebony dust and it worked quite well. Ron |

|

| Author: | Joe Beaver [ Sat Jun 10, 2006 4:21 am ] |

| Post subject: | |

I'm not so sure filling with dust or white epoxy or other such material would give you the look you want, or wear as well as you like. I could be wrong about that. Square silver wire would be my choice. But then you would have a problem on how to do the wider areas, like maybe cutting them from flat silver stock? Good luck and let us know what you come up with. |

|

| Author: | clavin [ Sat Jun 10, 2006 6:12 am ] |

| Post subject: | |

Either will work, but if you use dust, even silver or gold dust, which I use often, it will vary along with the variations in your routing. Wire is going to be much bolder, better color, cleaner to inlay, and flat out a better overall learning experience to do then just dust fillng. Dust isn't going to give you the quality results you most likely want for this project. If it was me doing it I would use 14K gold wire for the face outline, gold pearl for the eyes and other full face areas, silver dust or wire for the whiskers, and black pearl or pink mussel for the nose. Craig L. |

|

| Author: | James Orr [ Sat Jun 10, 2006 1:21 pm ] |

| Post subject: | |

The idea off wire is really interesting. I didn't even know about it as a material, to be honest. The idea of it intimidates me. :) I'm still daydreaming at this point. I really like the style of my sketch. I think it's a bit younger feeling, more of an illustration. Where would I find wire? |

|

| Author: | Joe Beaver [ Sat Jun 10, 2006 3:42 pm ] |

| Post subject: | |

You can get wire from any jewerly supply or lapidary supply. I use Rio Grande. They are www.riogrande.com. You may need to get a catalog from they. I think the gems & Findings is the one. You may want their tool catalog also. They have some pretty nice stuff. |

|

| Author: | James Orr [ Sat Jun 10, 2006 4:46 pm ] |

| Post subject: | |

How deep do you think the routs need to be? I may be doing this in two ply veneer; does THAT make it impossible? |

|

| Author: | Mattia Valente [ Sat Jun 10, 2006 7:13 pm ] |

| Post subject: | |

I used square wire (1mm square and 1.5mm square) pure silver wire in my last big fancy inlay project, got mine from Cookson Gold in the UK (as I'm in europe) and I found it really quite easy and pleasant to work with. Cuts with fret nippers (soft), shapes easily by hand and with a few pliers, bit of filing for sharp points, and dead easy to install. I routed as deep as the wire was, so either 1mm or 1.5mm. |

|

| Author: | Joe Beaver [ Sun Jun 11, 2006 1:32 am ] |

| Post subject: | |

[QUOTE=James Orr] How deep do you think the routs need to be? I may be doing this in two ply veneer; does THAT make it impossible? [/QUOTE] First let me tell you I have only used silver to do the little curly que things that come off of grape vines. Your project is of a much larger scope. Maybe someone more experienced will come along and advise. But, what I would do: Pick out the wire you want to use first. The width will tell you how big of an end mill to get. (I'd try for one about .005 wider than the wire) and the depth of the wire will tell you how deep you need to rout. I'd consider something like Sterling Silver Rectangle wire, Dead Soft, .079" x .039" (Rio Grande # 100-525) and use a .045 end mill (American Carbide # 82045). They also have a .040 end mill but it might be a little tight, maybe not. If you use veneer be careful you don't sand through it. |

|

| Author: | Barry Daniels [ Mon Jun 12, 2006 3:09 am ] |

| Post subject: | |

I think this will be a lot more difficult than is being made out. Some of the design has a lot of lines crossing and bending back on themselves. Trying to route these out freehand is going to leave a lot of little wood islands. Single lines are hard enough but the overlapping stuff will be very frustrating. Also, forget about the veneer because that will make it even more difficult. Also, size is a consideration. The area needed for a design this complex is probably much larger than a fingerboard or peghead provides. I advise picking a simple design with normal inlay methods for your first effort. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|